Charity Golf Day

July 1, 2019Lights Out.

Factories of the Future. Lights out Manufacturing

Lights out manufacturing is a term that you may, or may not have heard of. Often it is assumed to be a modern development in the manufacturing industry, but it is actually a methodology that was first mentioned in the mid-1950s. However, with the recent technological advancements across all sectors, we are entering a new era of automation ─ and lights out manufacturing driving the change.

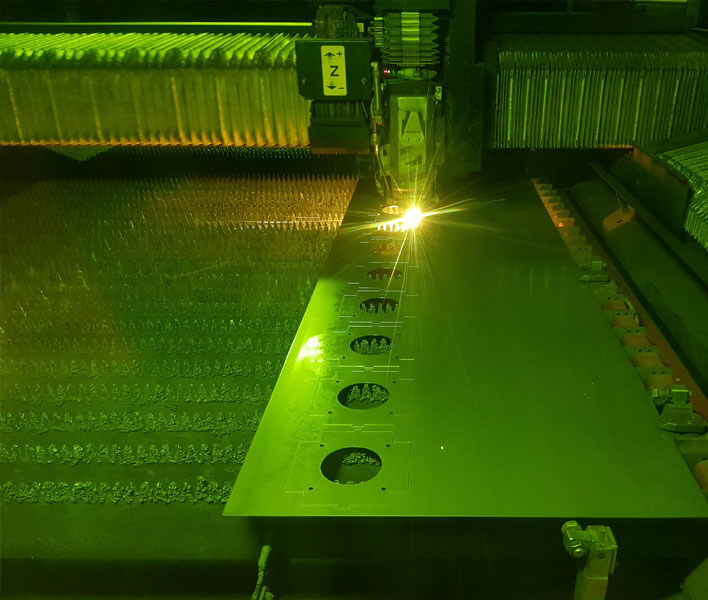

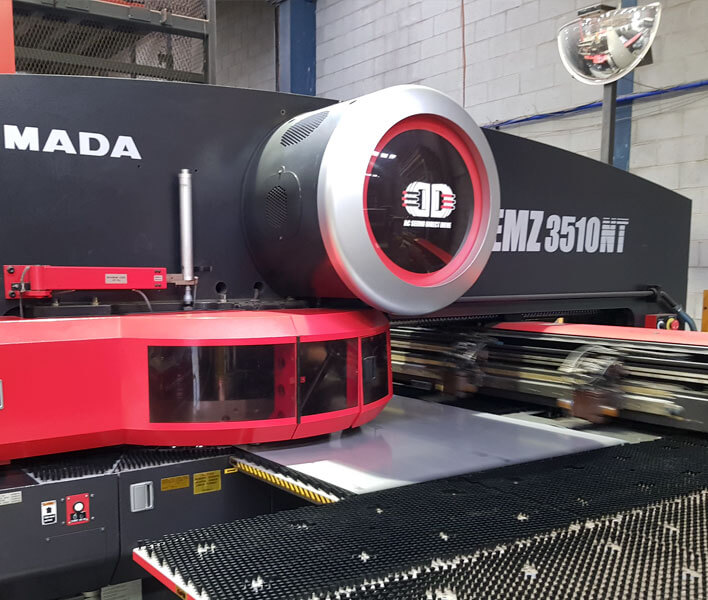

Automation and amada

Well, at FORM2000, we have partnered with the Japanese giant AMADA, with this we have the very best automation on the market, and we use it to its full extent. Our factories feature a myriad of unmanned work stations, including our AMADA FOL laser-cutting, AMADA 3510 turret punch, AMADA Astro press brake, OTC robot welding cells and our AMADA FLW dual welding cells, as well as our Motoman fastener insertion. These varying autonomous stations allow us to provide the most efficient service for our customers and clients, as well as impeccable and consistent quality on the end-product.

Forefront of industry

Lights out manufacturing are not coming to the forefront of the industry. The concept has been implemented for seven decades, but with the current capabilities of technology, it is becoming increasingly evident that the factory of the future will be, potentially, entirely automated.

As Douglas Peterson of America’s collaborative robot maker, Univeral Robots states:

“Robots are uniquely suited to any manufacturing task that is dirty, dangerous or dull. If the process doesn’t require human dexterity, mental agility or problem-solving skills, then it can be done by a robot.”

Benefits About Lights Out Manufacturing

Though it may sound detrimental to the workforce, the increase in productivity was, of course, the drive back when this form of manufacturing first came in to play. However, in the modern day, other factors are more relevant; automation increases the safety, speed, and accuracy, while simultaneously reducing the cost of labour for manufacturers.

The benefits do not stop there, though. Technology is often synonymous with Artificial Intelligence (AI) nowadays, and with AI comes incredible advancements. Machines are now becoming more sophisticated and human-like, and are able to harvest data while working, which AI then analyses and implements its findings to better its own capabilities. AI is even able to find faults or bugs and troubleshoot on behalf of the machines without any human interaction.

The most significant advantage to lights out manufacturing, however, is the web that it spins. AI-equipped automatons can monitor every single step of the production line, collating and reporting information for the company’s systems. A feat like this is one which humans are, unfortunately, unable to achieve. In factories that feature automation, the network of machines, both reports and acts, before we are even able to see a fault or potential

What is Lights Out Manufacturing

Well, to simplify lights out manufacturing, it is a process of production which is free of human necessities like lighting or heating, ventilation and air conditioning. In essence, lights out manufacturing is a manufacturing process used in factories that run fully autonomously, without any human interaction or supervision. The next generation of technological advancement in automated manufacturing is set to make factories smarter and able to function, quite literally, with the lights out. This development will increase both the productivity, quality, and efficiency of the manufacturing industry across the spectrum.